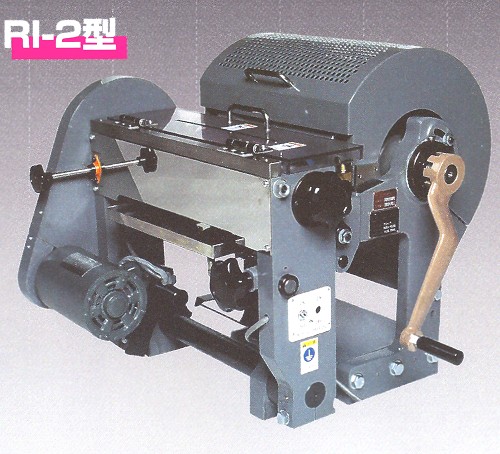

formastor-F 全自動(恆溫)(連續冷卻)變態(熱膨脹)紀錄測定裝置

formastor-F

全自動(恆溫)(連續冷卻)變態(熱膨脹)紀錄測定裝置

Full Automatic Transformation Measuring Equipment

廠牌:代理

供應商:大台北尖端儀器有限公司

聯絡電話:02-2531-0981

| 快速詢價 |

行動條碼QR Code

全自動的變態紀錄測定裝置,可用於金屬材料,特殊鋼材等的金屬組織變態及熱處理特性的測定裝置,為高周波加熱的巧妙應用。適用特殊鋼材的T.T.T測定、C.C.T測定、一般熱膨脹測定用以及變態測定的萬能測定裝置。

將一個尺寸3x10 mm的試片焊接於直徑=0.2R熱電偶的一方,插入如圖中所示設置的石英管和石英棒中。試片是以無線電頻率感應線圈加熱,透過噴嘴噴灑於內線圈上的冷卻介質冷卻,由過程中變態的差異獲取熱膨脹,可測量並紀錄鐵及鋼的金屬構造變態以及熱處理特性。溫度,膨脹值和時間資料記載於記錄器上可被讀取。自動操作/分析/溫度變態檢測,可獲得連續冷卻變態(C.C.T)和恆溫變態(C.C.T)的曲線圖。

*升溫速率100 deg.C/秒。

*冷卻速率300 deg.C/秒。 (He:900至400 deg.C)

*擴張範圍 50,100,250,500微米/ FS

*真空10-3 Pa.

A specimen in dia.=3 x L=10 mm with thermocouple dia.=0.2R welded on one side is inserted into a quartz tube and a quartz rod is set as shown in the drawing. The specimen is heated in radio frequency induction coils and cooled by cooling media sprayed through nozzles on inner coil by grasping thermal dilation by differential transformer during the process, transformation of metallic structure of iron and steel and also thermal treatment characteristics can be measured / recorded. Temperatures, dilation quantity and time data memorized in the data logger are read out and automatically operated / analyzed = transformation temperature detected so that CCT / TTT curves are obtained.

|

|

|

|

* Heating Rate

|

100 deg.C / sec.

|

|

* Cooling Rate

|

300 deg.C / sec. ( He: 900 to 400 deg.C )

|

|

* Dilation Range

|

50, 100, 250, 500 micro-m /FS

|

|

* Vacuum

|

10-3 Pa. order

|

Download : Specifications