Digox 602 dac 導電度脫氣裝置

Digox 602 dac

導電度脫氣裝置

Degassed Acid Conductivity

廠牌:Dr. Thiedig

供應商:聯宙科技股份有限公司

聯絡電話:02-22320556

| 快速詢價 |

The conductivity in water-steam cycle in power plants is an important measurement.

It must be distinguished between:

- Specifi c conductivity

which records the sum of all charge carriers and is mainly caused by enriched alkalising agents.

- Acid conductivity

In cation fi lter, the H+ from the exchanged cations combine with OH- from alkalizing agents to water. The remaining conductivity is determined by the autoprotolysis of the pure water plus the impurities in the form of anions, i.e. also CO32-.

To operate a steam turbine, the acid conductivity must not exceed a threshold of typically 0.2 μS/cm.

The following causes for increased conductivity are possible:

•unclean piping system, high corrosion conditions

•cooling water leakage in the condenser

•atmospheric air-in leakage with CO2-impact

•organic substances in the boiler feed water - CO2- impact after heating

- Degassed Cation conductivity

For the shortest possible start-up phase, the acid conductivity must be measured without the infl uence of the conductivity caused by dissolved CO2. Thus the threshold for operation of the turbine is reached faster. The dissolved CO2 rises up the conductivity, but does not harm the turbine.

Therefore, it is necessary to remove the carbonic acid from the sample and to measure the conductivity again (degassed acid conductivity). Thus, on one hand, the startup phase can be signifi cantly reduced. On the other hand, the system can be monitored for organic substances and atmospheric air ingress.

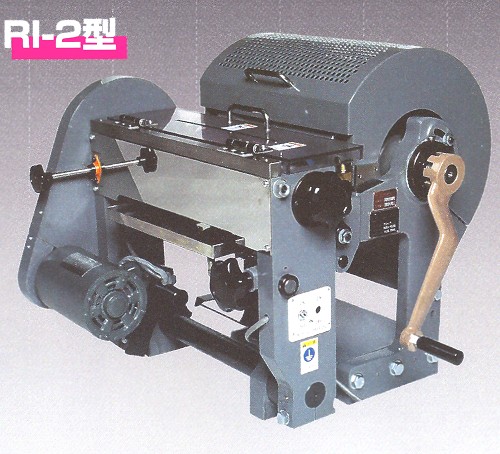

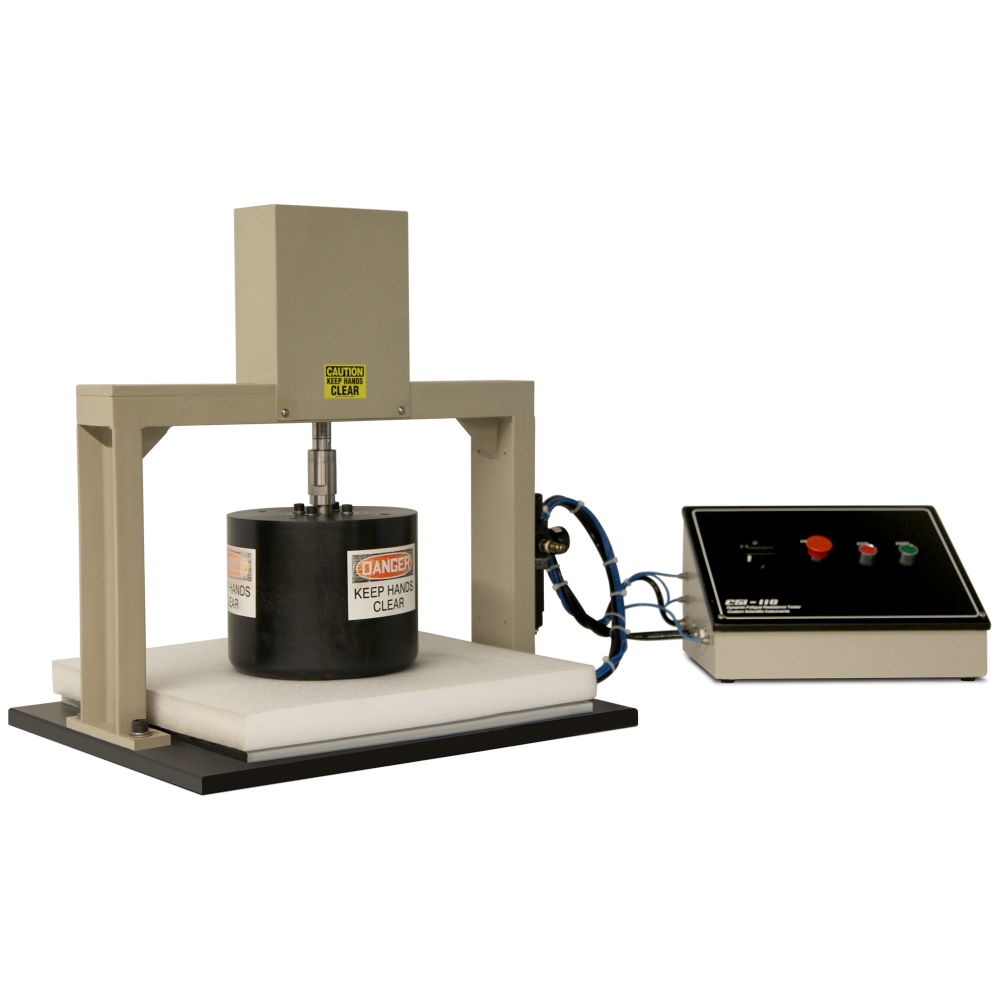

With the Digox 602 dac you have a universal measuring instrument at your disposal for this kind of tasks. In the compact design, you have fi rst a double conductivity measuring including a cation fi lter, automatic venting and pH calculation according to VGB-S006, then a separating operable degassing unit with conductivity measurings before and after degassing. Depending on the effi ciency, the degassing can be calculated to 100 %.

ADVANTAGES:

•Degassing and measurement of all conductivities at the same, not elevated sample temperature

•No heating up, therefore no gas emissions of other volatile acids

•No inert gas required, air-conditioning by means of air treatment

•High gain of degassed carbonic acid

•Very short response times t90 < 90 s for degassing unit

•Regenerative operating chemicals for cation exchanger

•Very low power consumption < 60VA

•Available as retrofit option for existing measurement of the cation conductivity: Digox dac basic

•Simple flow adjustment and stabilization with built-in flow stabilizer

•Improved efficiency of the degassing >90%, with switchable calculation to 100 %

•Highly accurate measurements of temperature and conductivity

The analyser Digox 602 dac ensures very short start-up times of the power plant and a simple, safe operation.