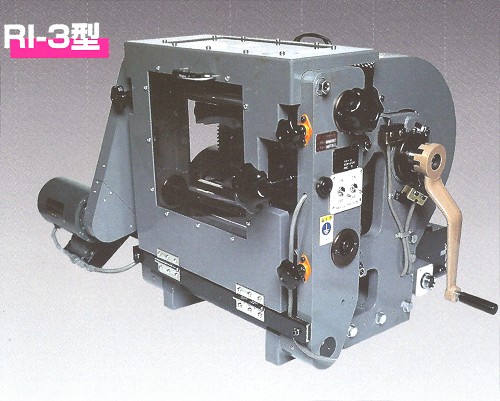

RI-3 RI-3 印刷適性試驗機(2色印刷)

RI-3

RI-3 印刷適性試驗機(2色印刷)

RI-3 PRINTABILITY TESTER

廠牌:代理

供應商:大台北尖端儀器有限公司

聯絡電話:02-2531-0981

| 快速詢價 |

行動條碼QR Code

用途:

該試驗機設計用於印刷適性的評估測試,包括印刷油墨、紙張、輥輪等等性能評估。

通過模擬測試,用戶可以獲取與實際印刷相同的測試結果,該儀器操作簡便,無須特殊培訓。用戶可以將本機印刷的樣品同採用國際標準印刷的標準試樣直接對比以評估材料印刷適性的好壞,不僅僅表述印刷壓力、速度、墨層厚度或紙張表強等等印刷適性。從實際生產的角度出發,該機將幫助使用者控制產品質量,分析工廠的產品問題來源。

特點:

該試驗機的測試過程即為一種將油墨轉印至緊貼於印刷滾筒上的紙張上的簡單印刷操作。油墨轉印過程由橡膠滾輪完成。

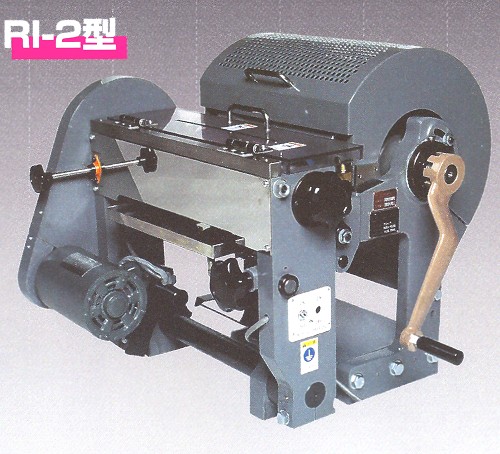

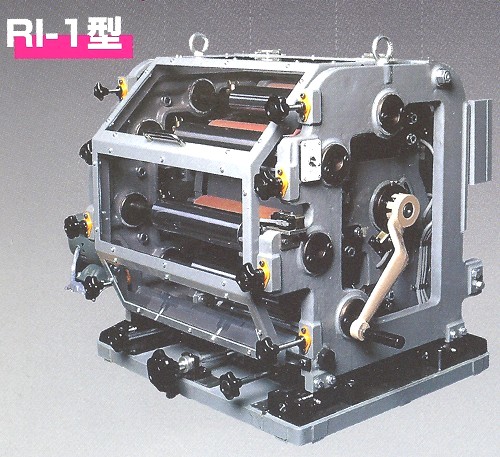

RI-1型繞印刷滾筒(impression cylinder)一圈有四個印刷單元,滾筒轉一圈完成一個四色印刷。RI-2型為單色印刷,RI-3型為3色印刷。所有型號的印刷機理簡單、操作方便。

- 用於紙張的平滑性、油墨受理性、油墨吸收性、耐剝離性、掉毛、透印、漏印以及其它特性的評估測試。

- 用於油墨特性的評估,例如色調、油墨遮蓋性、印墨疊印,油/水分離性,油墨未乾造成的污損,紙張印刷中的可操作性能評估。

描述:

- RI-1型有一個印刷滾筒和四個油墨轉印單元。 RI-2型有一個印刷滾筒和一個油墨轉印單元。RI-3型有一個印刷滾筒和兩個油墨轉印單元。

- 油墨轉印單元配有一個剛性滾和一個膠滾,滾輪測試表面面積為1,000cm2。

- 滾輪轉速為500r.p.m.。

- RI-1型的四個印刷單元象衛星一樣安置於印刷滾筒的周圍。

- 兩個滾輪可通過手動,瞬間與印刷滾筒接觸或分離。

- 鋼滾與橡膠滾,或者橡膠滾與印刷滾筒之間的壓力相互間精確可調。

- 需要時橡膠滾可方便快捷地卸下/安裝。

- 橡膠滾用作印刷工作中的平台滾輪。

- 印刷滾筒的表面平滑,滾筒於安置紙條,手動操作。

規格:

| 型號 |

RI-1型

|

RI-2型

|

RI-3型

|

| 印刷色數 |

4

|

1

|

2

|

| 紙張尺寸(最大) |

187mmx257mm

|

187mmx257mm

|

187mmx257mm

|

| 橡膠滾尺寸 |

Ø65mmx250mmL

|

Ø65mmx250mmL

|

Ø65mmx250mmL

|

| 金屬滾尺寸 |

Ø65mmx265mmL

|

Ø65mmx265mmL

|

Ø65mmx265mmL

|

| 電源 |

AC100V, 400W

|

AC100V, 400W

|

AC100V, 400W

|

| 金屬滾轉速 |

500r.p.m.

|

500r.p.m.

|

500r.p.m.

|

| 相對轉速 |

100r.m.p.

|

100r.m.p.

|

100r.m.p.

|

| 印刷滾筒尺寸 |

Ø300mmx300mmL

|

Ø300mmx300mmL

|

Ø300mmx300mmL

|

| 機械落地尺寸 |

985mmx663mm

|

709mmx612mm

|

735mmx578mm

|

| 機械高度 |

620mm

|

512mm

|

540mm

|

| 淨重(毛重) |

290kg (350kg)

|

170kg (225kg)

|

190kg (255kg)

|

選配裝置特性:

| 型號 | RI-1型 | RI-2型 | RI-3型 |

| 無段變速式輥筒驅動單元 | 可配置 | 可配置 | 可配置 |

| 電源 | DC100V, 200W | DC100V, 200W | DC100V, 200W |

| 轉速單元 | 40-120 r.p.m. | 40-120 r.p.m. | 40-120 r.p.m. |

| 潤濕裝置 | 可配置 | 可配置 | 無 |

| 橡膠輥尺寸 | Ø62mmx250mmL | Ø62mmx250mmL | |

| Molton厚度 | 2 mm | 2 mm | |

| 三輥裝置(印板安裝裝置) | 無 | 可配置 | 無 |

| 橡膠輥尺寸 | Ø75mmx250mmL | ||

| 印刷輥筒尺寸 | Ø65mmx250mmL |

RI-1型(4色刷)・RI-2型(1色刷)RI-3型(2色刷)3種類

用途

RIテスター(Rotay Ink Taster)はJIS-5701K「平版インキ及び凸版インキの試験方法」で被印刷物とインキの印刷適性を試験評価する試験器の一つに指定されております。

RIテスターは大日本印刷株式会社中央研究所のご指導のもとで主として紙とインキの印刷適性を試験評価するために開発された試験器ですが、実際の印刷条件を再現した試験が制度良く短時間にできる特長のためCCM(Computer Color Monitor)の標準見本色の作成、インキ以外の紙に印刷する薬液の受容性・色合い・艶等の試験評価、さらには化粧品の皮膚へののり具合等の試験評価にその用途を広げております。

これまでの使用実績からRIテスターはインキに限らず、液体とその液体の塗布される物質との間に受容性・発色・艶等を試験評価する場合に広く使用できます。

RIテスターは大日本印刷株式会社中央研究所のご指導のもとで主として紙とインキの印刷適性を試験評価するために開発された試験器ですが、実際の印刷条件を再現した試験が制度良く短時間にできる特長のためCCM(Computer Color Monitor)の標準見本色の作成、インキ以外の紙に印刷する薬液の受容性・色合い・艶等の試験評価、さらには化粧品の皮膚へののり具合等の試験評価にその用途を広げております。

これまでの使用実績からRIテスターはインキに限らず、液体とその液体の塗布される物質との間に受容性・発色・艶等を試験評価する場合に広く使用できます。

USES

This instrument is designed to examine printability of printing ink, paper roller, blanket, fountain solution and so on .

You can get the dame results as practical printing without any problem.

It is very easy to handle, so you do not need any skilled operator. And also you can evaluate which material has better printability by comparing the specimens to be tested with the known standard, not to express the printability such as printing pressure, speed, ink thickness or surface strength of paper etc. in theoretical figures.

From the practical point of view, it will help you to control the quality and to analyze where the trouble come form in your plant.

You can make a selection of three models to meet your requirement.

特長

- 印刷機に近い剪断力をインキにしようするため実際の印刷条件を再現でき、試験結果と現実の印刷結果との間の差が小さい。

- 段取りが簡単で短時間に印刷適性の試験評価ができます。従って研究室のみならず生産の現場での品質評価の検査に使用できます。

- 展色胴に最大で10種類の被印刷物を取り付けられ、同一インキの10種類の被印刷物に対する印刷適性を同一印刷条件で同時に試験評価できます。

- 2、及び4分割ゴムロールを使用することにより同一印刷物に対する2または4種類のインキの印刷適性を同一印刷条件で同時に試験評価できます。

- 被印刷物Dry/Wet状態の表面強度・印刷光沢・吸収性・インキの乾燥のしやすさ・発色・印刷濃度・被印刷物の塗布モトリング等試験評価ができてその範囲が広い。

- 構成部品に剛性があり構造が簡単で加工精度が高いので試験結果に再現性があり、さらに使いやすく故障が少ない。従って上記の2の特長とあいまって生産の現場での厳しい使用に耐えられます。

- 小型でコンパクトな構造であるため机上に設置できます。

FEATURES

Tests are made in a simple operation of transferring ink which thoroughly mixed on the slub, to the paper feed onto the cylinder. The transfer of the ink is made by the rubber roller. Model RI-1 has four units the operation around the cylinder. Accordingly, one complete rotation of the cylinder results in a four-color over printing. The three-color or two-color over printing can be easily performed by dismounting one or two units. Model RI-2 is single color and Model RI-3 is two color.

Mechanism of both model is very simple and easy operation.

- Tests about smoothness, ink receptivity, ink absorbency, picking, fluffing, strike through, show-through and other characteristics of paper.

- Tests about ink characteristics such as color tone mileage, trapping, ink/water relationship offsetting, operation of paper.

構造と原理

RIテスターはゴムロールと金属ロールからなる練りロール、被印刷物を取り付ける展色胴、ゴムロールと金ロール/ゴムロールと展色胴の間の圧印調整装置、および金属ロールの駆動およびオシレーション装置から構成されます。インキ・ゲージで軽量したインキをゴムロールと金属ロールからなる練りロールに塗布した後、金属ロールを起動して一般には約1分間、500R.P.Mの回転数と100R.P.Mのオシレーションでゴムロールとの間でインキに剪断力を作用させてインキを円周方向と幅方向に薄く均一に練ります。インキが円周方向と幅方向に薄く均一に練れた後、金属ロールを停止してゴムロール上のインキを展色胴に取り付けた被印刷物に移します。

Description

- RI-1 has one impression cylinder and four ink transfer units. RI-2 has one impression cylinder and one ink transfer units. RI-3 has one impression cylinder and two ink transfer units.

- Ink transfer unit being equipped with one steel roller and one rubber roller. The surface area of roller is 1,000cm²

- Revolution of each roller is 500rpm.

- Each of the ink transfer units of RI-1 is located at the rigid impression cylinder, which is arranged like a satellite.

- A pair of roller can be simultaneously contacted with or can throw off be cylinder by handle.

- Impression between steel and rubber roller or rubber roller and impression cylinder are adjustable each other precisely.

- Rubber roller can be dismounted from the tester easily and quickly when it is necessary.

- Rubber roller works as a plate roller for the impression cylinder and steel roller functions as vibrator.

- The surface of the impression cylinder is smoothly ground. The cylinder is equipped with paper gripper. It is rotated manually.