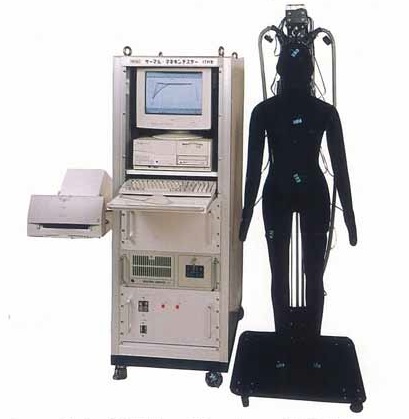

P41510, P41511, P41512 加拿大式游離度及濾水時間測定器(自動數償)P41510/P41511/P41512

P41510, P41511, P41512

加拿大式游離度及濾水時間測定器(自動數償)P41510/P41511/P41512

Canadian Freeness & Dewatering time Tester automatic with digital display and

廠牌:代理

供應商:大台北尖端儀器有限公司

聯絡電話:02-2531-0981

| 快速詢價 |

行動條碼QR Code

Applicable standards:

ISO 5267-2

TAPPI T 227

SCAN C21 und M4

PAPTAC C.1

APPITA P260

etc.

標準游離度儀是用於測定各種紙漿的水懸浮液的濾水速率,並由游離度(簡稱CSF )概念表述。濾水速率反映了纖維經過打漿或精磨的情況。標準游離度測定儀被廣泛應用於造紙工業生產中打漿過程的檢驗,造紙技術的制定以及科研院所的各種造紙制漿實驗中,是研究制漿造紙不可缺少的測量儀器。

加拿大標準游離度是指在規定的條件下,用加拿大游離度測定儀測定1000mL含量為(0.3±0.0005)%、溫度20°C的漿料水懸浮液的濾水性能,以該儀器側管流出的水的體積(mL)表示CFS值。該儀器為全不銹鋼製造。使用壽命長。

應用範圍:紙漿、複合纖維

適用標準:

ISO 5267-2

TAPPI T 227

SCAN C21 和 M4

PAPTAC C.1

APPITA P260

等

ISO 5267-2

TAPPI T 227

SCAN C21 和 M4

PAPTAC C.1

APPITA P260

等

特點:

- 用於測量稀漿懸浮液的脫水速率,並以游離度表示

- 完全由不鏽鋼材質製成

- 經 Paprican 測試

- 脫水室由輕質聚甲醛製成(易於操作和清潔)

3 種型號可選:

- 機械式

- 電子測定結果,數字顯示和數據傳輸(氣動升降)

- 電子測定結果,數字顯示、數據傳輸,帶溫度補償和濃度校正

產品敘述

具有數字顯示、溫度補償和濃度校正的型號:

加拿大標準游離度測定儀用於測量在漿料製備(精煉)過程中對纖維的功,因此是評估紙漿特性的主要工具。該儀器由一個脫水室和一個安裝在堅固支架上的速率測量漏斗組成。將1公升濃度為0.3%的紙漿懸浮液經由帶孔篩板排入一個有底部和側孔的漏斗中。側孔的流出物收集到量筒中,用超音波感測器測量並以數位方式顯示結果。同時測量懸浮液的實際溫度,並自動校正結果。任何與0.3%的偏差都應在數位控制面板上輸入,然後讀取以毫升CSF為單位的完整補償結果。

測試說明

將排水室放置到位。將量筒放置到位,以接收側孔的流出物。攪拌的同時,將1000毫升均勻的紙漿懸浮液轉移到一個乾淨的量筒中。蓋上遠離度測試儀的排水室底部,打開頂蓋。用手蓋上量筒頂部,將量筒倒置180°三次,混合樣品,注意不要失去漿料。在此階段,盡可能避免將空氣引入漿料中。將漿料緩慢但快速地倒入量筒中。傾倒結束時,漿料應在腔體中幾乎靜止。這可以透過將漿料傾倒在腔體內部周圍,並在中心完成傾倒來實現。立即關閉頂蓋,按下「停止」鍵並打開底蓋。打開底蓋後等待5秒,然後按「開始」鍵開始測試。當側孔的流出停止後,應在數位控制面板上輸入懸浮液濃度,然後讀取以毫升CSF為單位的完全補償結果。

將排水室放置到位。將量筒放置到位,以接收側孔的流出物。攪拌的同時,將1000毫升均勻的紙漿懸浮液轉移到一個乾淨的量筒中。蓋上遠離度測試儀的排水室底部,打開頂蓋。用手蓋上量筒頂部,將量筒倒置180°三次,混合樣品,注意不要失去漿料。在此階段,盡可能避免將空氣引入漿料中。將漿料緩慢但快速地倒入量筒中。傾倒結束時,漿料應在腔體中幾乎靜止。這可以透過將漿料傾倒在腔體內部周圍,並在中心完成傾倒來實現。立即關閉頂蓋,按下「停止」鍵並打開底蓋。打開底蓋後等待5秒,然後按「開始」鍵開始測試。當側孔的流出停止後,應在數位控制面板上輸入懸浮液濃度,然後讀取以毫升CSF為單位的完全補償結果。

規格

所有型號:

所有型號:

- 排水艙內裝有校正篩板

- 漏斗內裝有校正噴嘴

- 所有部件均採用防腐蝕材料製成

M型 (P41510):

手動型號,採用防腐蝕材料製成。打開空氣閥即可開始測試。結果在量筒上讀取。

手動型號,採用防腐蝕材料製成。打開空氣閥即可開始測試。結果在量筒上讀取。

D型 (P41511):

與上述相同,但透過按下顯示器上的「開始」按鈕開始脫水。數字顯示 CSF 值。

與上述相同,但透過按下顯示器上的「開始」按鈕開始脫水。數字顯示 CSF 值。

T 型 (P41512):

與 D 型相同,但配備鍵盤,用於輸入實際漿液濃度、自動溫度測量和補償。按下「Start」(啟動)按鈕即可開始脫水。

與 D 型相同,但配備鍵盤,用於輸入實際漿液濃度、自動溫度測量和補償。按下「Start」(啟動)按鈕即可開始脫水。

CSF 或 ml 顯示器

3 個脫水等級,用於測量脫水時間

溫度補償(顯示實際值和補償值)

3 個脫水等級,用於測量脫水時間

溫度補償(顯示實際值和補償值)

技術參數

電源:230 V,50 Hz(適用於 D 型和 T 型)

供水:無

壓縮空氣:無

尺寸(寬 x 深 x 高):38 x 33 x 72 cm

淨重:29 kg

毛重:40 kg

電源:230 V,50 Hz(適用於 D 型和 T 型)

供水:無

壓縮空氣:無

尺寸(寬 x 深 x 高):38 x 33 x 72 cm

淨重:29 kg

毛重:40 kg

Applicable standards:

ISO 5267-2

TAPPI T 227

SCAN C21 und M4

PAPTAC C.1

APPITA P260

etc.

Features

-

For measuring the rate of drainage of a dilute pulp suspension and expressing it in terms of freeness

-

Completely made of stainless steel materials

-

Tested by Paprican

-

Drainage chamber made of lightweight Polyacetal (easy to handle and clean)

-

3 models available:

-

Mechanical model

-

Electronic determination of results with digital display and data transfer (pneumatic lifting)

-

Electronic determination of results with digital display, data transfer, with compensation for temperature, and consistency correction

Description

Version with digital display, temperature compensation and concentration correction:

The Canadian Standard Freeness Tester measures the degree of work done on the fibres during stock preparation (refining) and is therefore a primary tool in the evaluation of the characteristics of pulp. The apparatus consists of a drainage chamber and rate measuring funnel on a sturdy support. 1 litre of pulp suspension at 0.3% concentration drains through a perforated screen plate into a funnel provided with a bottom and a side orifice. The discharge from the side orifice is collected in a graduated cylinder, measured by an ultrasonic sensor and the result displayed digitally. The actual temperature of the suspension is measured simultaneously and the result corrected automatically. Any deviation from 0.3% is entered at the digital control panel before reading the fully compensated result in ml CSF.

Test description

Place the drainage chamber in position. Place the measuring cylinder in position to receive the discharge from the side orifice. Whilst stirring, transfer 1,000 ml of homogeneous pulp suspension to a clean measuring cylinder. Close the bottom of the chamber of the freeness tester and open the top lid. Mix the sample by closing the top of the cylinder with the hand and invert the cylinder through 180° three times, without losing the stock. As much as possible, avoid introducing air into the stock at this stage. Pour the stock gently but as rapidly as possible into the chamber. At the end of the pouring, the stock should be almost motionless in the chamber. This can be achieved by pouring the stock around the inside of the chamber and finishing the pouring in the centre. Immediately close the top lid, press “Stop” and open the bottom lid. Allow 5 sec to elapse from the time of opening the bottom lid, then press “Start” to begin the test. When the discharge from the side orifice has stopped, the concentration of the suspension should be entered at the digital control panel before reading the fully compensated result in ml CSF.

Place the drainage chamber in position. Place the measuring cylinder in position to receive the discharge from the side orifice. Whilst stirring, transfer 1,000 ml of homogeneous pulp suspension to a clean measuring cylinder. Close the bottom of the chamber of the freeness tester and open the top lid. Mix the sample by closing the top of the cylinder with the hand and invert the cylinder through 180° three times, without losing the stock. As much as possible, avoid introducing air into the stock at this stage. Pour the stock gently but as rapidly as possible into the chamber. At the end of the pouring, the stock should be almost motionless in the chamber. This can be achieved by pouring the stock around the inside of the chamber and finishing the pouring in the centre. Immediately close the top lid, press “Stop” and open the bottom lid. Allow 5 sec to elapse from the time of opening the bottom lid, then press “Start” to begin the test. When the discharge from the side orifice has stopped, the concentration of the suspension should be entered at the digital control panel before reading the fully compensated result in ml CSF.

Specifications

All versions:

All versions:

-

Calibrated screen plate in drainage chamber

-

Calibrated jet in funnel

-

All parts made of non-corrosive materials

Version M (P41510):

Manual model made of non-corrosive materials. Opening the air-cock starts the test. The result is read on the graduated cylinder

Manual model made of non-corrosive materials. Opening the air-cock starts the test. The result is read on the graduated cylinder

Version D (P41511):

As above, but de-watering is started by pressing the “Start” button on the display. CSF value displayed digitally.

As above, but de-watering is started by pressing the “Start” button on the display. CSF value displayed digitally.

Version T (P41512):

As version D, but with keypad for entering the actual stock concentration, automatic temperature measurement and compensation. De-watering is started by pressing the “Start” button

As version D, but with keypad for entering the actual stock concentration, automatic temperature measurement and compensation. De-watering is started by pressing the “Start” button

CSF or ml display

3 de-watering levels for measuring the de-watering time

Temperature compensation (displays the actual value and compensated value)

3 de-watering levels for measuring the de-watering time

Temperature compensation (displays the actual value and compensated value)

Technical data

Electricity: 230 V, 50 Hz (for version D and T)

Water supply: None

Compressed air: None

Dimensions (WxDxH): 38x33x72 cm

Net weight: 29 kg

Gross weight: 40 kg

Electricity: 230 V, 50 Hz (for version D and T)

Water supply: None

Compressed air: None

Dimensions (WxDxH): 38x33x72 cm

Net weight: 29 kg

Gross weight: 40 kg

.jpg)