|

金鳴實業有限公司本公司成立於1987年,迄今已邁入第23年,持續穩定成長,為台灣地區之專業超低溫設備,冷凍乾燥機及高真空乾燥系統製造廠商。

本公司以自有品牌KINGMECH,專注研發、設計、製造、生產 超低溫設備 ULTRA LOW TEMP. DRYER,冷凍乾燥機 FREEZE DRYER及高真空乾燥系統 VACUUM DRYER等。

本公司產品為低溫乾燥,廣泛應用於:生物科技,學校,研究院所,健康食品業,醫學研究等凡產品對溫度敏感且易質變之乾燥。

創立於民國76年,專業製造真空冷凍乾燥機、食品冷凍乾燥整廠設備、超低溫急速冷凍系統、壓縮空氣之淨化系統、高溫氫氧焰水焊機、生化實驗及製藥機器。 |

|

|

| 真空冷凍乾燥機 FREEZE DRYER SYSTEM |

|

|

APPLICATIONS:

| - |

BIOLOGICAL, BIO-CHEMICAL, LABORATORY RESEARCH, MEDICAL, PHARMACY, ENZYMES, VACCINES, CLINICAL BLOOD ANALYSIS, AND DRY FOR OTHER TEMPERATURE SENSATIVE PRODUCTS. |

| - |

FOOD PROCESS:GARLIC, ONION, MUSHROOM, VEGETABLES, FRUIT CHIP, INSTANT FAST FOOD, COFFEE, TEA, MEAT, FISH, ROYAL JELLY ETC. | | |

| ‧ |

FREEZE DRYERS APPLICATION & FEATURE |

|

|

FEATURES:

THE FREEZE DRYING TECHNIQUE DIFFERENCE TO OTHER ORDINARY DRYING METHODS IS THE MATERIAL TO BE DRIED MUST BE SOLIDLY FROZEN BEFORE AND SUBLIMATE BY A VERY HIGH VACUUM AND A CONTROLLED HEAT INPUT, I.E. ICE TRANSFORMS DIRECTLY TO VAPOR BY PASSING THE INTERMEDIARY LIQUID PHASE. |

| - |

PRODUCTS EXTREME DRYNESS IS 1-3% MOISTURE CONTENT FOR LONGTERM STORAGE. |

| - |

KEEP THE ORIGINAL PRODUCTS STRUCTURE, COLOR & TASTE. |

| - |

PRODUCTS EASY TO REHYDRATION. |

| - |

PRODUCTS NO OXYGENATION AND DETERIORATION. |

|

THE FREEZE DRYING IS THE HIGHEST-TECHNOLOGY OF ALL DEHYDRATION METHODS. |

|

|

| BASIC THEORY CHART FOUR CONDITIONS OF FREEZE DRYING: |

|

(1) CONDENSER MUST BELOW –40℃

(2) PRODUCT MUST BE FULLY FROZEN SOLIDLY.

(3) VACUUM MUST DOWN TO 5 MILLITORR~4 TORR.

(4) PRODUCT TEMP. CONTROL BETWEEN –40℃~+65℃ HEAT INPUT TO THE PRODUCT. | |

|

|

|

|

| ‧ |

COMPACT TYPE FREEZE DRYERS |

|

|

FEATURES: |

| - |

CLEAR DRUM VACUUM CHAMBER, OPTION ADD FOR ROLLED OR UNROLLED PREFREEZE BATH. |

| - |

BENCH TYPE EASY TO INSTALL, MAINTAIN, OPTION FOR 3 MIN. TIME DELAY START. |

| - |

3/8, 1/2, 5/8 THREE SIZE IN ONE VACUUM VALVE, FROM 12 PORTS. |

| - |

CONDENSER SURFACE AREA IS 750 CM2 COAXIAL COIL TYPE. |

| - |

AUTOMATIC POWER OVERLOAD PROTECT OF COMPRESSOR, VACUUM PUMP. |

| - |

60∮ , 90∮ TWO SIZE IN ONE VACUUM BOTTLE ADAPTER . |

|

THE FREEZE DRYING IS THE HIGHEST-TECHNOLOGY OF ALL DEHYDRATION METHODS. |

|

| |

|

|

|

|

| ‧ |

DRUM BENCH TYPE FREEZE DRYERS |

|

|

FEATURES: |

| - |

CLEAR DRUM VACUUM CHAMBER, OPTION ADD FOR ROLLED OR UNROLLED PREFREEZE BATH. |

| - |

BENCH TYPE EASY TO INSTALL, MAINTAIN, OPTION FOR 3 MIN. TIME DELAY START. |

| - |

3/8, 1/2, 5/8 THREE SIZE IN ONE VACUUM VALVE, FROM 12 PORTS. |

| - |

CONDENSER SURFACE AREA IS 750 CM2 COAXIAL COIL TYPE. |

| - |

AUTOMATIC POWER OVERLOAD PROTECT OF COMPRESSOR, VACUUM PUMP. |

| - |

60∮ , 90∮ TWO SIZE IN ONE VACUUM BOTTLE ADAPTER . |

|

THE FREEZE DRYING IS THE HIGHEST-TECHNOLOGY OF ALL DEHYDRATION METHODS. |

|

| |

|

|

|

|

| ‧ |

DRUM, MANIFOLD MOBILE TYPE FREEZE DRYERS |

|

|

FEATURES: |

| - |

DRUM OR L MANIFOLD, OPTION ADD FOR ROLLED OR UNROLLED PREFREEZE BATH. |

| - |

MOBILE TYPE EASY TO MAINTAIN, INSTALL, OPTION FOR 3 MIN, TIME DELAY START. |

| - |

3/8, 1/2, 5/8 THREE SIZE IN ONE VACUUM VALVE, FROM 12~36 PORTS. |

| - |

AUTOMATIC POWER OVERLOAD PROTECT OF COMPRESSOR, VACUUM PUMP. | |

|

|

|

|

| ‧ |

SHELF TYPE FREEZE DRYERS |

|

|

FEATURES: |

| - |

SHELF TYPE FD12-24 OPTION ADD TOP L-MANIFOLD FROM 6-12 PORTS. |

| - |

AUTOMATIC POWER OVERLOAD PROTECT OF COMPRESSOR, VACUUM PUMP, CIR. PUMP , HEATER ETC. OPTION FOR 3 MIN, TIME DELAY START | |

|

|

|

|

| ‧ |

BULK FREEZE DRYER SYSTEMS FOR BIO-CHEMICAL. PHARMACY. AND FOOD |

|

|

PRODUCTION TYPE FREEZE DRYERS |

| ‧ |

BASIC THEORY CHART & PS./ TEMP. CHART OF WATER |

|

PRODUCTION TYPE FREEZE DRYERS |

| ‧ |

FD 20L-6S .FD 50L-8S .FD 100L-9S .CONTROL PANNEL |

|

PRODUCTION TYPE FREEZE DRYERS |

| ‧ |

DRYING CHAMBER & CONDENSER FOR FD300L-16S, FD500L-16S, FD1000L-16S |

|

2 STAGE VACUUM PUMP |

| ‧ |

FOR FD20L-6S . FD50L-8S . FD100L-9S |

|

2 STAGE HI-QUALITY REFRIGERANT COMPRESSOR UNIT |

| ‧ |

FOR FD20L-6S, FD50L-8S, FD100L-9S, FD300L-16S, FD500L-16S, FD1000L-16S |

|

HEAT EXCHANGER |

| ‧ |

FOR FD300L-16S, FD500L-16S, FD1000L-16S |

|

CONTROL PANNEL & FLOW CHART |

| ‧ |

FOR FD300L-16S, FD500L-16S, FD1000L-16S |

|

-40℃ PREFREEZING ROOM |

| ‧ |

FOR FD300L-16S, FD500L-16S, FD1000L-16S |

|

COOLING TOWER / CIR. PUMP & PIPING |

| ‧ |

FOR FD20L-6S, FD50L-8S, FD100L-9S, FD300L-16S, FD500L-16S, FD1000L-16S | |

|

|

|

|

| ‧ |

ACCESSORIES OF FREEZE DRYERS |

|

| - |

10C.C SCREW VIAL WITH RUBBER STOPPER & SCREW CAP 24.3φ X 58H |

| - |

10C.C VIAL WITH RUBBER STOPPER & ALLUMINUM CAP 23φ X 55H |

| - |

HI VACUUM GREASE |

| - |

HI VACUUM PUMP OIL |

| - |

3/8 . 1/2 . 5/8 THREE SIZE IN ONE VACUUM VALVE (PAT#218220) |

| - |

ALLUMINUM SCREW VIAL ADAPTER FOR 24.3φ SCREW VIAL |

| - |

1000C.C 300C.C PYREX VACUUM BOTTLE WITH 60φ 90φ TWO SIZE IN ONE RUBBER ADAPTER |

| - |

3 SHELVES DRYING CHAMBER (OPTION) 180φ X 160φ X 250H(mm) CLEARANCE 60-200mm a\ADJ. |

| - |

2 SHELVES VIAL STOPPERING DRYING CHAMBER (OPTION) 23φ X 55H VIAL /24PCS / TRAY X 2 CLEARANCE 60-200mm ADJ. | |

|

|

|

|

|

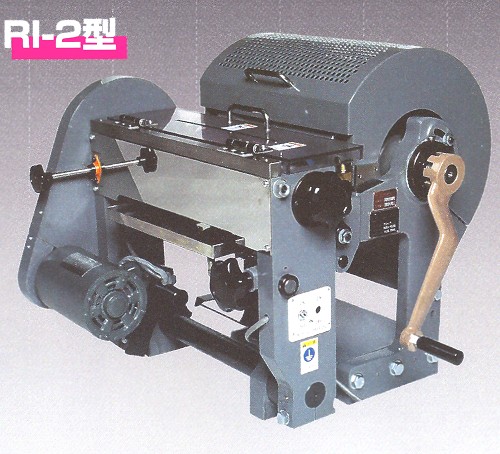

| 高溫氫氧焰水焊機 WATER WELDER |

|

|

BASIC THEORY:

JUST ADD DI-WATER AND PLUG THE PLUG. THEN YOU CAN GET THE MIXER GAS OF HYDROGEN & OXYGEN WHICH PASS THROUGH THE FAN TO CONDENSE WATER VAPOR.

THE FUNCTIONS OF BOOSTER ARE TO ADD THE ENTHALPY, TO REDUCE THE FLAME TEMPERATURE, TO RISE THE PRESSURE OF GAS AND TO INCREASE THE ENERGY. IT'S A VERY ECONOMICAL METHOD TO HAVE A HI-TEMPERATURE FLAME.

FEATURES:

| - |

FUEL ARE WATER、ELECTRI POWER AND A LITTLE OF SOLVENT. EASY TO GET AND STORAGE SAFTY. |

| - |

2H2 + O2 BURN 2H2O (VAPOR), THE VAPOR LEFT FROM BURNING IS NON TOXIC AND NON POLLUTION. |

| - |

GOOD DESIGNED MACHINE CONSTRUCTURE, FOR CONTINUOUS OPERATION. |

| - |

TORCH WITH BUILT-IN DEFUSION STONE, PRESSURE SWITCH, OVER-PRESSURE RELIEVE VALVE, TO PROTECT THE MACHINE ABSOLUTLY SAFTY. |

| - |

FLAME TEMPERATURE RANGE IS UP TO 3420℃ OR CAN BE DOWN TO 1200℃. |

| - |

EASY TO CHANGE THE FLAME SIZE. ESPECIALLY IN VERY FINE FLAME USUAGE AREA.TIP ORIFICE SIZE ARE FROM 0.076mm¢ (30#) TO 1.056mm¢ (16#). |

| - |

COMPACT AND EASY OPERATION. |

APPLICATIONS:

| - |

METAL WELDING:LEAD-TIN SOLDERING, GOLD, SILVER, COPPER, BRASS BRAZING, FOR SPOT AND PLATE WELDING, SUCH AS EAR-RING, NECKLACE, CHAINS, FINGER RING, ETC, |

| - |

GLASS PROCESS:AMPOULE SEALING, QUARTZ GLASS PROCESS, MERCURY SWITCH SEALING, GLASS CAPILARY TUBE FORMING, BENDING, ETC,. |

| - |

MOTOR INDUSTRY:STATOR COPPER-THREAD WELDING AND NO NEED TO PEEL THE COVER. |

| - |

HI-MELTING POINT METAL WELDING: THERMAL COUPLE THREAD WELDING, LED PLATE CONNECTING, COMPUTER STRIPPING TEFLON TAPE CABLE COVER PEELING AND CUTTING, GOLD WIRE BALL BONDING. |

| - |

SUN GLASSES HING'S WELDING. |

| - |

ARCRYLIC SURFACE OR EDGE FLAME POLISHING. |

| - |

TOOTH MOLD PIN HOLE MENDING. |

| - |

LEAD ACID BATTERY ELECTRODE PLATE WELDING. |

| - |

HEAT TREATMENT FOR SMALL PART AND PRECISE CRAFT. | |

|

| 壓縮空氣之淨化系統 COMPRESSED AIR CIEANSING SYSTEM |

|

| ‧ |

THE DIAGRAM OF COMPRESSED AIR CLEANSING SYSTEM |

|

THE COMPRESED AIR CONTAINS WATER MIST, DUST, OIL MIST, GREASE, AND OTHER PARTICLES. CAUSES OF DAMAGED KINETIC MECHANISM AND DEFECTED PRODUCTS. THERE FOR, IT MUST BE TREATED BY REFRIGERATED AIR DRYER, MICRO FILTERS, AND ADSORPTIVE DRYER ETC. |

|

|

| ‧ |

REFRIGERATED AIR DRYER SERIES |

|

FEATURES OF THE REFRIGERATED AIR DRYER

THE HIGH HUMID HOT COMPRESSED AIR BE PRECOOLED BY A AFTER COOLER, THEN ENTER TO THE FIRST HEAT EXCHANGER BE RECOOLED BY COLD DRYED AIR, THEN ENTER TO THE EVAPORATOR, THE AIR BE CHILLED TO 1.5℃ AND THE WATER MIST BE CONDENSED DROP DOWN, THEN DRAIN BY A AUTODRAIN. THERE FOR, THE COLD DRYED AIR BE WARMMED BY HIGH HUMID HOT AIR TO PREVENT WET OUTLET PIPING AND SAVE ENERGY. |

|

|

| ‧ |

ADSORPTIVE DRYER |

|

|

APPLICATIONS: |

|

- |

SMT, ELECTRONIC |

|

- |

FOOD, PHARMACY |

|

- |

INSTRUMENT |

|

- |

LAB & HOSPITAL |

|

- |

BIO-CHEMISTRY |

|

- |

PRECISE INDUSTRY |

|

|

|

FEATURES: |

|

- |

HIGH EFFICIENCY MICROPROCESS |

|

- |

PLC CONTROL. |

|

- |

HEATLESS REGENERATION SAVE ENERGY AND LOW COST. |

|

- |

HIGH-TECH DESICCANT SAFTY AND LONG CHANGING TIME. |

|

- |

SPECIAL PRESSURE BALANCE DESIGN WITHOUT PRESSURE SHOCK DURING REGENERATION EXCHANGE. | |

|

|

| ‧ |

MICRO FILTER |

|

|

- |

5 MICRON |

|

- |

1 MICRON |

|

- |

0.01 MICRON |

|

- |

0.01 MICRON CARBON |

|

|

|

FEATURES: |

|

- |

ALUMINUM ALLOY HOUSING MAX. WORKING PRESSURE TO 16kg / cm2 |

|

- |

SIGHT GLASS DESIGN TO CHECK FILTER COLUMN. |

|

- |

DIFFERENT GRADE OF COLUMN CAN BE INSTALLED IN THE SAME HOUSING | |