Liquidus Point 玻璃液相點試驗

Liquidus Point

玻璃液相點試驗

Liquidus Point (ASTM C829), (Orton Gradient Tube Furnaces)

廠牌:ORTON/U.S.A.

供應商:建成科學儀器股份有限公司

聯絡電話:02-29103818

| 快速詢價 |

Liquidus Point Determination

(suitable for the ASTM C 829 method)

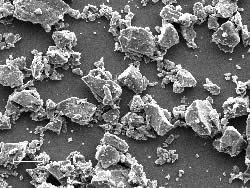

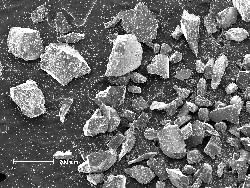

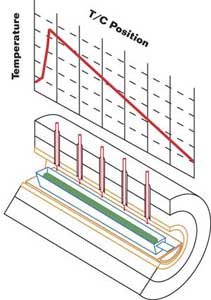

Samples of glass, frit, or cullet are poured into a platinum boat then placed into the hot Orton Gradient Furnace for 1 or 24 hours. The Orton Model GTF-MD-15/16 Series Furnace is a specially designed horizontal tube furnace with a controlled, reproducible, linear thermal gradient of approximately 120°C across a 12" long monitored zone, the temperature of the glass in the boat corresponding to its position along that 12" zone. The boat is removed hot and allowed to quench cool, freezing the glass in the state developed inside the furnace. Upon visual or microscopic inspection, the crystal boundary plane (the Liquidus Point) is located and the temperature of that plane is interpolated from the temperature/position relationship of the known gradient.

Glass Batch Studies Samples of the glass batch or raw materials are poured into one or several platinum boats, then placed into the Orton Gradient Furnace. The furnace can be hot or can be programmed for a specific thermal cycle. The Orton Model GTF-MD-15/16-L Series Furnace is a specially designed horizontal tube furnace with a controlled, reproducible, linear thermal gradient of approximately 320°C across a 16" long monitored zone, the temperature of the glass batch in the boat corresponding to its position along that zone. The sample boat can be removed hot and allowed to quench cool, freezing the batch in the state developed inside the furnace or the boat can cool inside the furnace. Upon visual inspection, the temperature of the zone of interest is interpolated from the temperature/position relationship of the known gradient.

Observe, measure or study the effects of temperature over a controlled temperature span of 120°C, 160°C, 240°C or 320°C in ONE firing.

Place an extruded column of a green ceramic, a row of pressed discs or parts, a trough of granular raw material, or a glazed substrate on the D-tube hearth and into the Orton MD Series Gradient Furnace. Set the controller for a specific thermal cycle, them walk away to perform other tasks. After the furnace cools, remove the samples and record their position on the D-tube hearth. Since one end of the row of materials was cooler then the other, you can immediately see how the range of firing temperatures affected the shrinkage, color, porosity, particle size, degree of vitrification, and other ceramic properties that are temperature dependent.

Place an extruded column of a green ceramic, a row of pressed discs or parts, a trough of granular raw material, or a glazed substrate on the D-tube hearth and into the Orton MD Series Gradient Furnace. Set the controller for a specific thermal cycle, them walk away to perform other tasks. After the furnace cools, remove the samples and record their position on the D-tube hearth. Since one end of the row of materials was cooler then the other, you can immediately see how the range of firing temperatures affected the shrinkage, color, porosity, particle size, degree of vitrification, and other ceramic properties that are temperature dependent.

The Orton Model GTF-MD-15 (1,500°C maximum) and GTF-MD-16 (1,600°C maximum) Series Furnaces are a specially designed horizontal tube furnaces with controlled, reproducible, linear thermal gradients of approximately 120°C across a 12" long monitored zone. The Orton Model GTF-MD-15L and GTF-16L Series Furnaces are longer versions with controlled, reproducible, linear thermal gradients of approximately 320°C across a 16" long monitored zone. Thermocouples on 2" centers monitor the temperatures along the gradient zone, so the temperature of the material at any position along the D-tube hearth is known. Visual or post firing analyses of sections taken from the fired material at any position along the D-tube hearth can be measured, recorded, and studied as a function of temperature.

The Orton GTF-MD Series Furnace is a specially designed horizontal tube furnace with a controlled, reproducible, approximately linear thermal gradient across a 12" or 16" long monitored zone.

|

|

![]() 下載本目錄文件請使用 PDF 檔案程式

下載本目錄文件請使用 PDF 檔案程式

The Model Liquidus Furnace Brochure download in a PDF format (142 KB).